CNC lathes are computer-controlled machines that shape objects by spinning them while they are being cut by a sharp blade. This type of machining is very precise and is used to create objects with a high level of accuracy.

Checkout this video:

What is a CNC lathe machine?

CNC lathe machines are computer-controlled lathes that automates the process of lathing. These machines are operated by a CNC operator who uses a computer interface to input the dimensions and tolerances of the desired product. The machine then lathes the product according to these specifications.

There are many benefits to using CNC lathe machines. These machines can produce products with much greater accuracy and consistency than can be achieved by hand. They also allow for much more complex designs to be lathed, such as those with multiple curves or multi-axis designs. In addition, CNC lathe machines are much faster than traditional lathes, which saves both time and money.

The history of the CNC lathe machine

The history of the CNC lathe machine can be traced back to the early 1950s when touch-screen panel control systems were first introduced. These early CNC lathes were large and expensive, and only a handful of companies could afford to purchase them. In the 1960s, numerical control (NC) systems began to be used in industrial settings, which allowed for greater flexibility and accuracy in manufacturing. However, these NC systems were still quite expensive and required special training to operate.

In the 1970s, personal computers (PCs) were introduced and this gave rise to the development of the first computer numerical control (CNC) machines. These CNC machines were smaller and more affordable than their predecessors, making them more accessible to a wider range of businesses. Today, CNC lathes are an essential piece of equipment in many manufacturing settings and continue to evolve with advances in technology.

How a CNC lathe machine works

CNC lathe machines are computer-controlled lathe machines that are used to create precise, symmetrical parts out of various materials. The machine uses a rotating cutting tool to remove material from the workpiece, which is held in place by a chuck. The cutting tool is guided by a computer program, which determines the shape and size of the final part.

The benefits of using a CNC lathe machine

A CNC lathe machine is a computer-controlled turning machine that can create high precision parts. The benefits of using a CNC lathe machine are numerous. Perhaps the biggest benefit is the fact that it can create parts with a very high degree of accuracy. This means that you can create parts that will fit together perfectly, without any gaps or other problems.

Another benefit of using a CNC lathe machine is the fact that it is very fast. With traditional methods, it can take a long time to create a single part. With a CNC lathe machine, you can create multiple parts in a fraction of the time. This can be a huge benefit if you need to produce large quantities of parts in a short amount of time.

Finally, another benefit of using a CNC lathe machine is that it is very versatile. You can use it to create parts out of almost any material. This includes both metals and plastics. This versatility means that you can use the CNC lathe machine to create parts for almost any application imaginable.

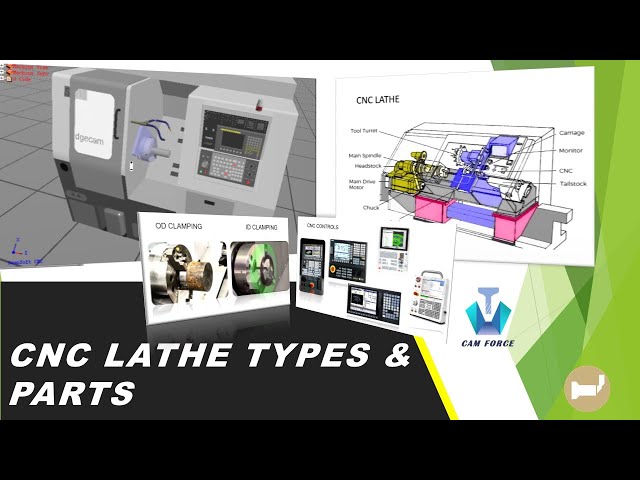

The different types of CNC lathe machines

Computer numerical control (CNC) lathes are turning machines whose movements are programmed by a computer. A CNC lathe is similar to a conventional lathe but with computer-control capabilities.

CNC lathes can be classified into three main types:

1. Turning Centers: These machines have integrated live tooling and sub-spindle capabilities, making them ideal for complex machining operations.

2. Swiss-type CNC Lathes: These machines are designed for small, precise parts with tight tolerances. They typically have live tooling and can perform various secondary operations.

3. Big Bore CNC Lathes: These machines are designed for large, heavy workpieces that require high spindle speeds and powerful cutting forces.

The features of a CNC lathe machine

A CNC lathe machine is a computer-controlled machine that is used to shape metal parts. The machine can be programmed to perform a variety of operations, including turning, drilling, and tapping. CNC lathes are equipped with a cutting tool that is mounted on a turret. The cutting tool is then fed into the workpiece, which is rotated at high speeds. The turret can be repositioned to allow the cutting tool to access different areas of the workpiece.

The advantages of a CNC lathe machine

The CNC lathe machine is a computer-controlled machine used for manufacturing precise and accurate parts. The machine is able to produce parts with tighter tolerances and greater accuracy than a conventional lathe machine. In addition, the CNC lathe machine is faster and more efficient, making it ideal for mass production.

The disadvantages of a CNC lathe machine

CNC lathe machines have many disadvantages. They are expensive, they require a high level of operator training, and they are not well suited for small shops.

The future of the CNC lathe machine

The CNC lathe machine is a computer-controlled machine tool that turns cylindrical objects. It is one of the most versatile machine tools, and can be used to create a variety of shapes and sizes, including threads, screws, gears, and dies.

historically, lathes were powered by a hand crank or a foot pedal. However, modern lathes are powered by computerized numerical control (CNC), which allows for greater accuracy and repeatability. CNC lathes can also be programmed to create more complex shapes than traditional lathes.

Lathes are used in a variety of industries, including automotive, aerospace, medical, and manufacturing. CNC lathes are especially well-suited for mass production of parts with high precision requirements.

As the demand for more precise and efficient machine tools increases, the CNC lathe will likely continue to play an important role in the manufacturing industry.

FAQs about the CNC lathe machine

CNC stands for computer numerical control. A CNC lathe machine is a lathe whose operations are controlled by a computer. This means that once the machine is programmed, it can be left to run on its own, without the need for constant supervision.

CNC lathes are used in a wide range of industries, from aerospace to medical manufacturing. They offer a high degree of accuracy and repeatability, which is why they are so popular.

If you’re thinking about buying or using a CNC lathe machine, here are some FAQs that might help you out:

-What are the benefits of using a CNC lathe machine?

CNC lathes offer a high degree of accuracy and repeatability, which is why they are so popular. They can also be programmed to produce complex parts that would be difficult or impossible to create using traditional methods.

-How much does a CNC lathe machine cost?

The cost of a CNC lathe machine will vary depending on the features and specifications that you require. However, you can expect to pay anywhere from $5,000 to $100,000 for a good quality machine.

-How do I choose the right CNC lathe machine for my needs?

It’s important to consider your specific needs before you purchase a CNC lathe machine.Think about the types of materials you’ll be working with, the complexity of the parts you’ll be creating, and your budget. Once you have a good idea of your requirements, you can start looking at different machines and comparing their features.

-Where can I buy a CNC lathe machine?

C NC Lathes prices