A 5 axis CNC machine is a computer numerically controlled machine that can perform five-axis machining. 5 axis CNC machining is a process where computer software is used to control the movements of a machine.

Checkout this video:

What is a 5 Axis CNC Machine?

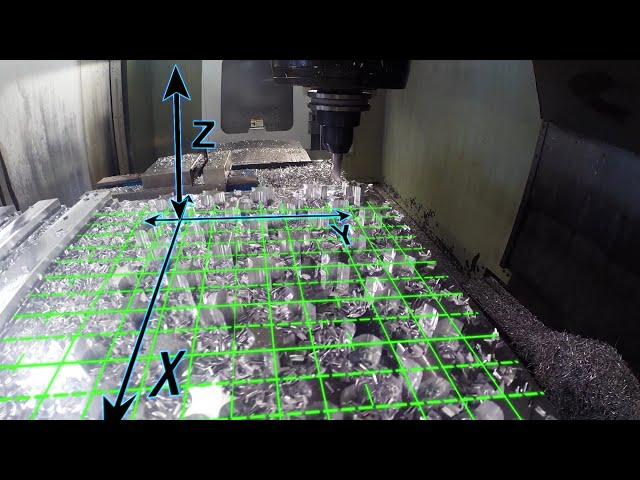

A 5 axis CNC machine is a numeric control device that can perform complex tasks such as milling, drilling and turning. These machines are controlled by a computer system that reads instructions from a CAD file or CAM program. The five axes of a 5 axis CNC machine refer to the different ways in which the cutting tool can move. In addition to the three linear axes (X, Y and Z), there are two rotational axes (A and B). This allows for more angles to be cut, which results in more accurate and precise images or shapes being created.

The Benefits of a 5 Axis CNC Machine

A 5 axis CNC machine is a computer numerical control (CNC) device that moves a workpiece on five axes. The CNC device is programmed to precisely follow a specified tool path. The movement of the workpiece is controlled by the machine, while the position and orientation of the cutting tool is positioned and oriented by the CNC device.

The benefits of using a 5 axis CNC machine are numerous. First, the use of a CNC device allows for greater accuracy and repeatability in the manufacturing process. Second, the use of five axes allows for more complex shapes to be machined than with traditional three-axis machines. Third, the use of five axes also allows for faster machining times, as well as increased material removal rates.Fourth,

5 axis CNC machines are also capable of performing multiple operations on a single workpiece, which reduces both machining time and setup time. Finally, 5 axis CNC machines are capable of producing parts that would otherwise be impossible to produce using traditional manufacturing methods.

The Different Types of 5 Axis CNC Machines

There are different types of 5 Axis CNC machines each with its own capabilities and advantages. The most common type is the simultaneous 5 Axis machine, which is capable of machining all five sides of a workpiece at the same time. This allows for greater efficiency and accuracy, as well as shorter lead times. Other types of 5 Axis CNC machines include the sequential 5 Axis machine, which machines one side at a time; the indexing 5 Axis machine, which can only rotate in two axes at a time; and the hybrid 5 Axis machine, which combines features of both the sequential and simultaneous machines.

How a 5 Axis CNC Machine Works

A 5 axis CNC machine is a computer-controlled machine that can perform five axis machining. This type of machining is generally used for creating complex parts, such as engine blocks or turbine blades. 5 axis machining is possible because of the additional two axes, which allow for more degrees of freedom when machining a part. In order to perform 5 axis machining, the CAM software must be specially programmed to control all five axes of the machine simultaneously.

The History of the 5 Axis CNC Machine

The 5 axis CNC machine was invented in the early 1970s by John T. Parsons, who was working at the Stanford Artificial Intelligence Laboratory at the time. His invention was inspired by the earlier work of Chuck Blish, who had developed a 3 axis CNC machine.

Parsons’ 5 axis CNC machine was designed to be controlled by a computer, and he used it to create a sculpture of a human face. This was one of the first examples of using a CNC machine to create a work of art.

Since then, the 5 axis CNC machine has been used for a wide variety of applications, including industrial manufacturing, woodworking, and even medicine. Today, there are many different types of 5 axis CNC machines available on the market, each with its own unique capabilities.

The Future of the 5 Axis CNC Machine

The 5 Axis CNC Machine is the future of the machining industry. This type of machine is able to produce parts with a higher degree of accuracy and repeatability than ever before. Additionally, the 5 Axis CNC Machine is much faster and more efficient than traditional machining methods, making it the perfect choice for a variety of applications.

5 Axis CNC Machine Myths

There are many myths and misconceptions about 5 axis CNC machines. In this article, we’ll dispel some of the most common ones.

1. Myth: 5 axis CNC machines are slower than 3 axis machines.

fact: 5 axis CNC machines can actually be faster than 3 axis machines, depending on the application. For example, when machining complex parts with multiple features, a 5 axis machine can often complete the job in fewer setups and with less tooling than a 3 axis machine.

2. Myth: 5 axis CNC machines are more expensive than 3 axis machines.

fact: While 5 axis CNC machines can be more expensive than 3 axis machines, the price difference is often much less than people think. In many cases, the extra cost of a 5 axis machine is offset by the increased productivity and efficiency that it offers.

3. Myth: 5 axis CNC machining is only for complex parts.

fact: While 5 axis machining is often used for complex parts, it can also be used for simpler parts that require accurate positioning or multiple features to be machined in one setup.

4. Myth: 5 axis CNC machines are difficult to operate.

fact: While 5 axis CNC machines can be more complicated to operate than 3 axis machines, they are not necessarily more difficult to learn how to use. With proper training, most people can learn how to operate a 5axis machine with relative ease.

5 Axis CNC Machine Maintenance

5-axis CNC machines have many components that require regular maintenance to function properly. These machines are used in a variety of industries, such as aerospace, automotive and medical.

The most common types of 5-axis CNC machines are horizontal and vertical machining centers. Horizontal machining centers have the spindle mounted on a horizontal axis and typically have a rectangular work envelope. Vertical machining centers have the spindle mounted on a vertical axis and typically have a round or square work envelope.

Both types of machines require regular maintenance to ensure accuracy and precision. The following is a list of 5-axis CNC machine maintenance tips:

1. Check the coolant level and pH balance regularly. The coolant should be at the proper level and pH to protect the machine from corrosion and scale buildup.

2. Inspect the cutting tools regularly. Cutting tools should be inspected for wear and damage before each use. Replace any damaged or worn cutting tools to prevent damage to the machine or workpiece.

3. Clean the machine regularly. Dust, dirt, and other debris can build up on the machine over time and cause problems with accuracy and precision. Be sure to clean the machine regularly to prevent these issues.

4. Check for loose bolts and nuts regularly. Loose fasteners can cause vibration and noise, as well as damage to the machine or workpiece. Be sure to check for loose fasteners on a regular basis and tighten them as needed.

5. Lubricate moving parts regularly. Lubrication helps keep moving parts operating smoothly and prevents wear on the components. Be sure to lubricate the moving parts of the machine on a regular basis according to the manufacturer’s guidelines

5 Axis CNC Machine Troubleshooting

One of the most common issues that can occur when using a 5 axis CNC machine is that the material being worked on can shift. This can cause problems with the finish of the product, and it can also cause safety issues. If you notice that your material is shifting, there are a few things that you can do to try to correct the problem.

First, check to make sure that the material is properly secured to the bed of the machine. If it is not, then you will need to replace whatever is holding it in place. In most cases, this will be a clamp or a vise. If you are using a vise, make sure that it is properly tightened. You may also want to try using more than one vise to hold the material in place.

Another thing that you can do is to increase the amount of pressure that you are applying to the material. This can be done by either manually increasing the pressure or by using a higher setting on the machine itself. If you are unsure about how much pressure to apply, then you should consult the owner’s manual for your specific model of machine.

If you are still having problems with your 5 axis CNC machine, then you may need to contact a professional for help. There are many companies that offer support and service for these types of machines. Find one in your area and give them a call. They should be able to help you troubleshoot the problem and get your machine running correctly again

5 Axis CNC Machine Tips

5 axis CNC machines are computer numerically controlled machine tools that have at least five axes of motion. Most commonly, these machines are used for machining parts with complex shapes, such as turbine blades and medical implants. These machines can be used for a variety of other applications as well, such as engraving and 3D printing.

There are a few different types of 5 axis CNC machines, each with its own strengths and weaknesses. The most common type is the portal milling machine, which has a horizontal spindle and a moving table that the workpiece is mounted on. These machines are very heavy and require large amounts of electricity to operate. Another type of 5 axis CNC machine is the gantry milling machine, which has a vertical spindle and a movable gantry that the workpiece is mounted on. These machines are lighter than portal milling machines and can be more efficient in terms of energy use.

5 axis CNC machining can be done with a variety of different materials, including metals, plastics, and composites. The most common type of material used in 5 axis machining is aluminum, due to its high strength-to-weight ratio and ease of machining. However, 5 axis machining can also be done with other materials such as stainless steel, titanium, and even wood.