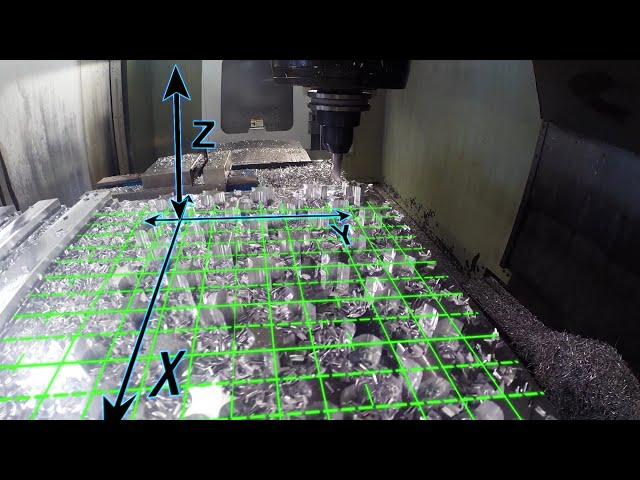

A 4 axis CNC machine is a computer controlled machine that can rotate on two additional axes beyond the standard X,Y and Z axes. This allows for more complex milling and drilling operations.

Checkout this video:

What is a 4-axis CNC machine?

A 4-axis CNC machine is a computer controlled machining center that has the ability to rotate the work piece on two additional axes (or directions) in addition to the standard X, Y and Z axes. This allows for more flexibility and creativity in machining, especially when it comes to machining complex shapes. There are many different types of 4-axis CNC machines available on the market today, each with its own unique capabilities. Some common applications for 4-axis CNC machines include:

-Machining complex shapes

-Machining multiple sides of a work piece

-Creating holes with different diameters on different sides of a work piece

-Machining curved or non-flat surfaces

4-axis CNC machines can be used for a wide variety of applications in both small shops and large factories. If you are considering purchasing a 4-axis CNC machine it is important to consult with an experienced machine shop or dealer to find the machine that best meets your specific needs.

How does a 4-axis CNC machine work?

4-axis CNC machines are computer controlled machining tools that have the ability to move in 4 different axes. The fourth axis is generally perpendicular to the other three (X, Y, and Z), and allows for increased flexibility when machining parts.

4-axis CNC machines are most commonly used in the aerospace and automotive industries, where parts often need to be machined at different angles. 4-axis CNC machines can also be used for more complex jobs, such as engraving or sculpting.

What are the benefits of using a 4-axis CNC machine?

4-axis CNC machines offer a number of benefits over traditional 3-axis CNC machines.

One of the biggest benefits is that 4-axis CNC machines offer more flexibility in terms of fabricating parts. With a 4-axis machine, you can rotate the workpiece on the fourth axis to mill features that are not possible with a 3-axis machine.

Another benefit of 4-axis CNC machines is that they can be used for more than just milling operations. Many 4-axis machines also have the ability to perform turning operations, which can be tremendously helpful when trying to fabricate complex parts.

Overall, 4-axis CNC machines are more versatile and flexible than their 3-axis counterparts, and as a result, they are becoming increasingly popular in a variety of applications.

What are the applications of 4-axis CNC machining?

4-axis CNC machining is a process that uses computer numerical control (CNC) technology to operate machine tools. The four axes are the X-axis, the Y-axis, the Z-axis, and the A-axis. The A-axis is also known as the rotational axis. 4-axis CNC machines can perform all of the tasks of 3-axis CNC machines and more.

4-axis CNC machining can be used for a variety of applications, including:

-Machining curved surfaces

-Creating contoured shapes

-Drilling holes on angled surfaces

-Cutting threads

-Milling dovetails

What are the advantages of 4-axis CNC over 3-axis CNC?

4-axis CNC machines offer a number of advantages over 3-axis CNC machines. With 4-axis machining, the workpiece can be rotated along the X-axis, allowing for more complex shapes and deeper cuts. In addition, 4-axis CNC machines can generate contoured surfaces more effectively than 3-axis CNC machines. As a result, 4-axis CNC machining is well suited for manipulating large, complex workpieces.

How much does a 4-axis CNC machine cost?

4-axis CNC machining is a CNC machining process in which the workpiece is rotated along two axes in addition to the standard X, Y, and Z axes. This allows for more complex shapes and profiles to be machined with greater precision than would be possible with traditional 3-axis CNC machines.

4-axis CNC machines typically cost more than 3-axis CNC machines, due to the added complexity of their design and construction. However, the increased precision and functionality offered by 4-axis machines can make them a worthwhile investment for many businesses.

What are the disadvantages of 4-axis CNC?

4-axis CNC has a few disadvantages when compared to other CNC types.

The first disadvantage is the increased complexity. 4-axis CNC machines are more complex than 3-axis machines, and as a result, they are more expensive and require more training to operate.

Another disadvantage of 4-axis CNC is that it is less versatile than other CNC types. 4-axis machines are limited to cutting linear materials, whereas 5-axis and 6-axis CNC machines can cut linear and curved materials.

Finally, 4-axis CNC machines have shorter tool life than other types of CNC machines. This is due to the increased vibration caused by the fourth axis of motion.

Despite these disadvantages, 4-axis CNC machines offer some advantages over other types of CNC machines. 4-axis machining can provide quicker cycle times and improved surface finish quality for certain applications.

What are the challenges of 4-axis CNC machining?

One of the challenges of 4-axis CNC machining is that it can be difficult to find the right software. 4-axis machines are becoming more popular, but there is still a lack of software that can fully utilize their potential. Another challenge is that 4-axis machining can be more expensive than traditional CNC machining, due to the additional hardware and software required.

Is 4-axis CNC worth it?

4-axis CNC machines are becoming increasingly popular as the technology improves and the price comes down. But what is 4-axis CNC and is it worth the investment?

4-axis CNC machines have an extra axis, which means that they can cut on all four sides of the material. This extra degree of freedom allows for more complicated cuts and shapes to be made.

The main advantage of 4-axis CNC is that it opens up a whole new range of possibilities for designers and manufacturers. It also means that more complex shapes can be cut out of materials, which can save time and money.

The downside of 4-axis CNC is that it is more expensive than traditional 3-axis CNC machines. It also requires a higher level of skill to operate, so it might not be suitable for everyone.

If you think that 4-axis CNC could benefit your business, then it might be worth investigating further. However, if you’re not sure whether it’s right for you, then you might want to stick with traditional 3-axis CNC machines for now.

How to choose a 4-axis CNC machine?

With so many different types of CNC machines on the market, it can be difficult to know which one is right for your needs. If you’re looking for a machine that can handle more complex projects, a 4-axis CNC machine may be the right choice for you.

4-axis CNC machines are computer controlled milling machines that have the ability to move in four different directions: X, Y, Z, and A (rotational). This gives them a lot more flexibility than traditional 3-axis machines, which can only move in three directions.

One of the main benefits of 4-axis CNC machines is that they can be used for more complex projects. Because they can rotate in addition to moving horizontally and vertically, they can create shapes and patterns that would be very difficult or impossible to create with a 3-axis machine.

Another benefit of 4-axis CNC machines is that they tend to be more accurate than their 3-axis counterparts. This is because they have one fewer degree of freedom, which means there is less opportunity for error.

If you’re considering buying a 4-axis CNC machine, there are a few things you should keep in mind. First, make sure that you understand the capabilities of the machine before you make your purchase. There’s no point in buying a machine that’s more complex than you need it to be – you’ll just end up wasting money.

Second, take into account the size of the projects you’ll be working on. If you only ever intend to work on small projects, then there’s no need to invest in a large and expensive 4-axis machine. Conversely, if you plan on working on large projects regularly, then it’s worth spending the extra money on a 4-axis machine that’s up to the task.

Finally, think about the ease of use when choosing your 4-axis CNC machine. Some machines are very user friendly and easy to set up and operate, while others require much more experience and knowledge. If you’re not sure which kind of machine is right for you, it’s always best to consult with an expert before making your final decision.