A turret lathe is a specific type of lathe that uses a turret to hold the cutting tools. This turret allows for quick and easy tool changes during operation.

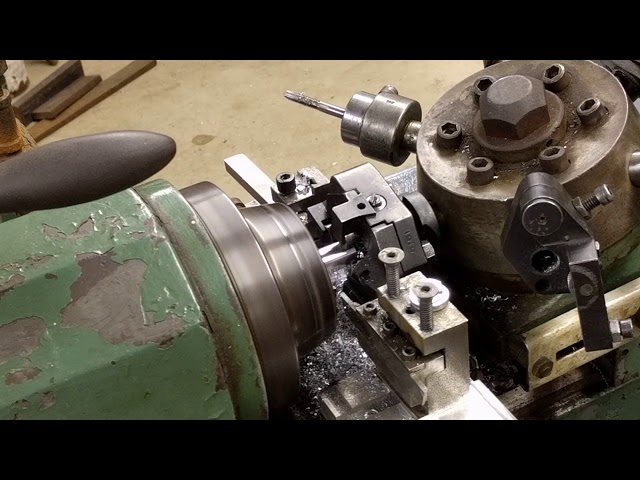

Checkout this video:

What is a turret lathe?

A turret lathe is a type of lathe that uses a turret to hold various cutting tools. This allows for quicker tool changes and more complex shapes to be machined.

The history of the turret lathe

The turret lathe was first developed in the early 19th century. It was invented by Jean-Jacques PERREAUX, a French engineer. The first turret lathes were very large and bulky, and they could only be used to turn large diameter objects.

The first turret lathes were powered by waterwheels or steam engines. In 1847, Joseph Whitworth developed the first turret lathe that was powered by an electric motor. This machine was much smaller and more precise than the previous versions.

Turret lathes became very popular in the late 19th and early 20th centuries. They were used to create many of the objects that we use today, such as car parts, machine guns, and even airplanes.

The different types of turret lathes

A turret lathe is a type of lathe that has a rotating turret on the headstock, which holds various cutting tools that can be brought into play as needed. This allows for quick tool changes and increased efficiency when compared to a standard lathe. Turret lathes come in several different types, each designed for specific purposes.

The most common type of turret lathe is the engine lathe, which is used for a variety of general purpose machining operations. These lathes typically have two or three turrets, and can be outfitted with various attachments such as power feeds, hydraulic copy attachments, and collet chucks.

Another common type of turret lathe is the toolroom lathe, which is designed for more precise work than an engine lathe. These lathes have heavier construction and more powerful drives, and often have features such as digital readouts and programmable controls. They are typically used for batch production of small parts, or for prototyping new designs.

Still other types of turret lathes include the capstan lathe, used for repetitive work such as drilling or tapping; the gang tool lathe, with multiple turrets arranged in a line; and the turbine blade lathe, which is specially designed for machining turbine blades.

The advantages of turret lathes

Turret lathes were invented in the late 1800s and quickly gained popularity due to their many advantages over traditional lathes. Turret lathes are faster, more precise, and more versatile than traditional lathes, making them an essential tool in any machine shop.

Turret lathes work by mounting the cutting tool on a turret, or rotating table, that is positioned next to the workpiece. The turret can be quickly rotated to bring the cutting tool into position, allowing for fast, precise cuts. In addition, the turret can be equipped with multiple cutting tools, giving the turret lathe the ability to perform multiple operations without having to stop and change tools.

While turret lathes offer many advantages over traditional lathes, they are also more expensive and require more maintenance. However, for most applications, the benefits of turret lathes far outweigh the disadvantages.

The disadvantages of turret lathes

Even though there are many advantages to using a turret lathe, there are also some disadvantages that you should be aware of before you decide whether or not this type of lathe is right for your business. One of the main disadvantages of turret lathes is that they are generally more expensive than other types of lathes on the market. This is because they are designed for heavy duty industrial use and they have many features that other lathes do not have.

Another disadvantage of turret lathes is that they can be more difficult to operate than other types of lathes. This is because they have more moving parts and more complex controls. If you are not familiar with operating a turret lathe, it is important to take some time to learn how to use one before you decide to purchase one for your business.

Turret lathes also tend to be larger and heavier than other types of lathes, which can make them difficult to move around your shop. If you need to move your turret lathe around frequently, you may want to consider renting one instead of buying one outright.

How to operate a turret lathe

A turret lathe is a type of metalworking lathe that is used for precise and quick turning of various diameters of material. It has a turret, which is a cylindrical toolholder that can be indexable, meaning that it can be rotated to a desired position and locked in place. This allows the turret lathe operator to quickly change between various tooling without having to remove and replace each tool one at a time.

Tips for operating a turret lathe

A turret lathe is a type of metalworking lathe that is generally used for making small to medium sized parts. The name “turret lathe” comes from the fact that it has a Turret, which is basically a tool holder that can be rotated. This turret holds various cutting tools, which the operator can use to create the desired shape on the workpiece.

Turret lathes can be either manually operated or CNC (computer numerically controlled) operated. CNC turret lathes are more expensive than manual ones, but they offer much higher accuracy and repeatability.

Here are some tips for operating a turret lathe:

– Always wear proper safety gear, including safety glasses and hearing protection.

– Make sure that the workpiece is properly secured in the chuck before beginning any machining operation.

– Slowly increase the speed of the spindle until it reaches its optimal speed for the cutting operation you are performing.

– Use sharp cutting tools to achieve the best results and to extend the life of your tooling.

– Always perform a test cut on a scrap piece of material before cutting into your actual workpiece.

– Be sure to regularly check for coolant leaks and top up the coolant tank when necessary.

Maintenance tips for a turret lathe

Turret lathes are a type of lathe that uses a turret to hold various cutting tools. The turret, which is mounted on a swivel, can be rotated to different positions so that different cutting tools can be used. Turret lathes are very versatile and can be used for a variety of different tasks.

There are a few things you can do to keep your turret lathe in good working condition:

-Regularly oil and clean the machine to prevent rust and buildup.

-Check the alignment of the cutting tools to ensure they are cutting properly.

-Make sure the cutting tools are sharpened regularly.

-Be careful not to over tighten the bolts when mounting the cutting tools onto the turret.

Troubleshooting a turret lathe

If you are having problems with your turret lathe, there are a few things that you can do to troubleshoot the issue. First, check to see if the machine is properly lubricated. If it is not, then you will need to add lubricant to the proper areas. Next, check for any loose parts or bolts. Tighten or replace any parts that are not functioning properly. Finally, if you are still having problems, consult the manual for your specific model of turret lathe.

FAQs about turret lathes

Q: What is a turret lathe?

A: A turret lathe is a type of lathe that uses a turret to hold various cutting tools. The turret can be indexed, meaning that it can be rotated to different positions, allowing the user to quickly change between different cutting tools. Turret lathes are often used for mass production because they can be set up to perform many different operations quickly and efficiently.

Q: How does a turret lathe work?

A: A turret lathe works by rotating a workpiece (such as a piece of metal) against a cutting tool (such as a drill bit or end mill) that is held in the turret. The rotation of the workpiece and the cutting tool create friction, which generates heat. This heat is then transferred to the workpiece, causing it to soften and deform. The deformation can be controlled by the speed at which the workpiece is rotated and by the force with which the cutting tool is applied.

Q: What are some advantages of using a turret lathe?

A: Turret lathes offer many advantages over other types of lathes, such as improved productivity, greater flexibility, and easier tool changes. They are well suited for mass production because they can be set up to perform many different operations quickly and efficiently. In addition, turret lathes are more forgiving than other types of lathes if an incorrect tool is used or if the wrong speed is selected; this makes them ideal for use in environments where operator training may be minimal.

Q: What are some disadvantages of using a turret lathe?

A: While turret lathes offer many advantages over other types of lathes, there are also some disadvantages to consider. One downside is that they can be more expensive than other types of lathes; however, this cost is often offset by their increased productivity and flexibility. Another potential disadvantage is that their increased complexity can make them more difficult to operate and maintain; however, this disadvantage is typically minimized by proper operator training and regular maintenance.